Strength

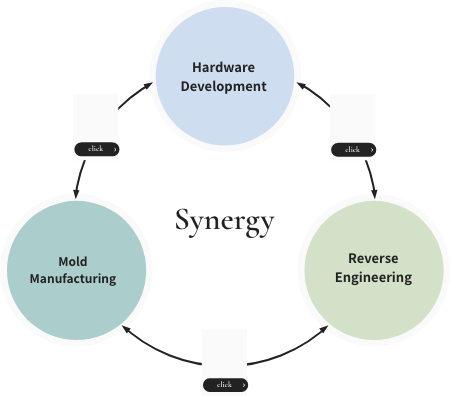

PGF lab’s StrengthsPGF lab specializes in three core businesses of hardware development, mold manufacturing, and reverse engineering,

and continues to deploy services to meet demands for job shop type production and speedy delivery amidst our rapidly-changing times.

Leveraging our strengths in development speed, adaptability to diverse specifications, and manufacturing QCD batch management,

we make one-stop service, from development through to manufacturing, into a reality.

By supporting manufacturing product development, we contribute to the success of our clients.

-

Hardware Development

With a policy of “quick, affordable, small, robust,

and beautiful”, we perform design development in diverse areas,

such as electronic and communication devices. -

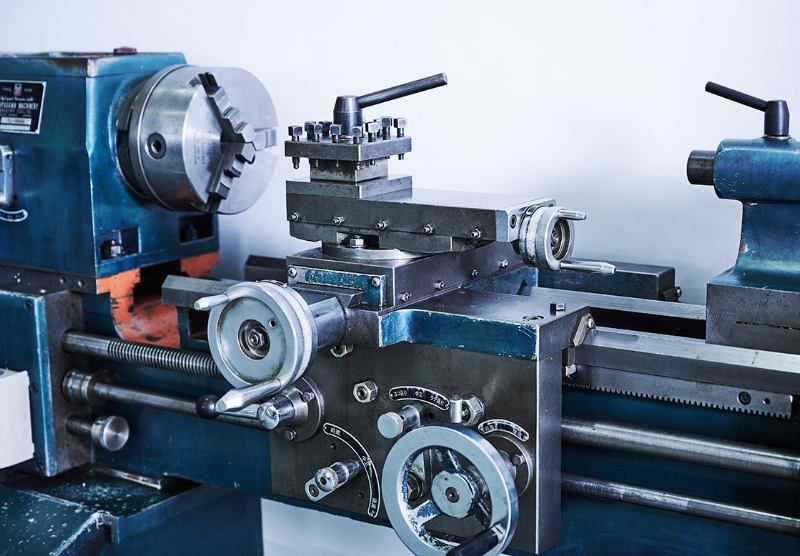

Mold Manufacturing

We create countless manufacturing opportunities

through methods including mold design, mold machining,

and injection molding. -

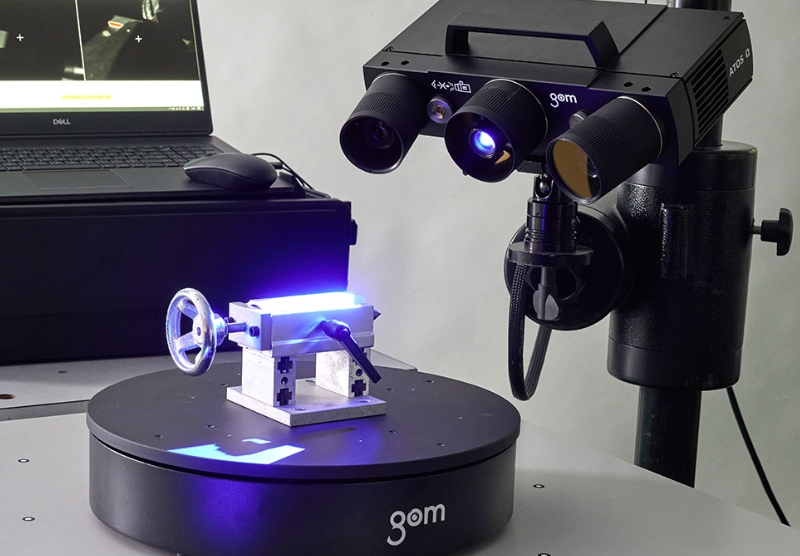

Reverse Engineering

Challenging part and product manufacturing jobs

become possible through 3D analysis and data creation.

The strong affinity of our three businesses creates synergy that allows us to deliver a wide variety of service benefits. This diagram illustrates the synergy between our three areas of business. Click on number 1, 2, or 3 to display a summary of our service benefits below.

Development

Case Studies

As our clients strive to achieve monozukuri — Japan’s traditional concept of excellence in manufacturing —

they face a wide range of issues on a day to day basis.

We direct our technical prowess and passion to create a unique path to success for each client.

Here are a few such examples from our many achievements.

-

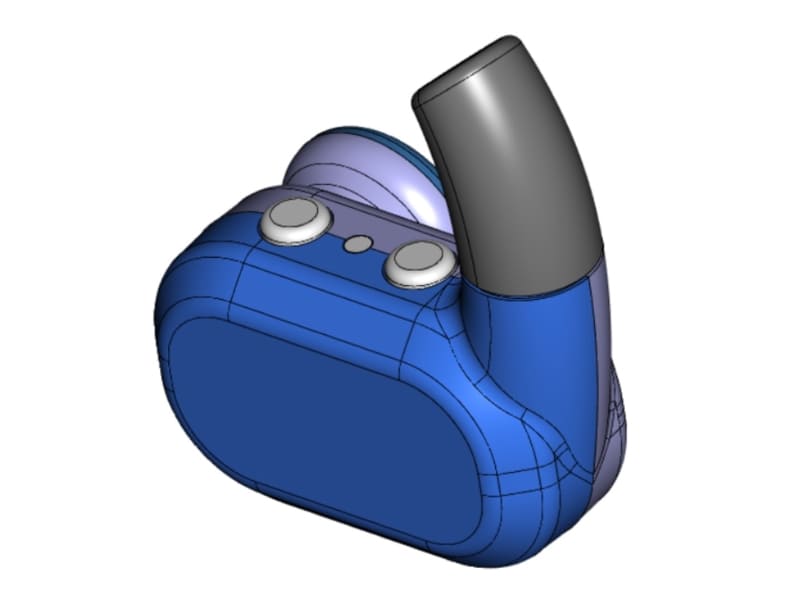

Case Study

1Wireless Earphone Design

This project began with consultation regarding disappointing progress after consigning design to another company. We successfully designed the wireless earphone housing in a short time frame.

-

Case Study

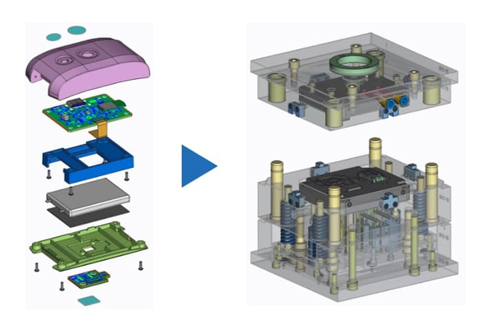

2Cold Wallet Terminal Development

and Manufacturing ContractIn this project, we were contracted for complete service, from product, mechanical, and circuit design to PCB artwork and manufacturing.

-

Case Study

3Internal Clock Reading Device

This project began from the challenging task of monitoring the human ‘internal clock’, and covered the entire scope from product development through to manufacturing.

-

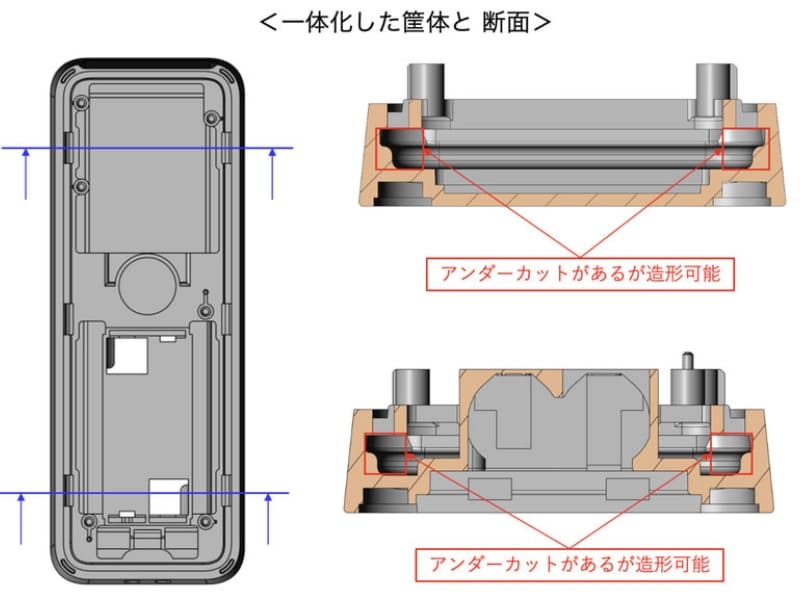

Case Study

4Cost-Reduction Design

of 3D Printer-Modeled ProductThe product is the housing of the AndGo, Inc. cold wallet. Due to small production lots, we avoided manufacturing molding dies, and instead manufactured these parts by 3D printer.

Corporate Overview

| Trade Name |

PGF Co., Ltd. |

|---|---|

| Established |

February 2017 |

| Areas of Business |

・Hardware Development |

| Offices |

Yokohama Office (Hardware Development/Reverse Engineering) |

| CEO |

Ryuhei Noguchi |

| Fiscal Term |

End of January |

| Banks of Account |

Sumitomo Mitsui Banking Corporation, The Hachijuni Bank, Ltd., |